2025.08.22

2025.08.22

Industry News

Industry News

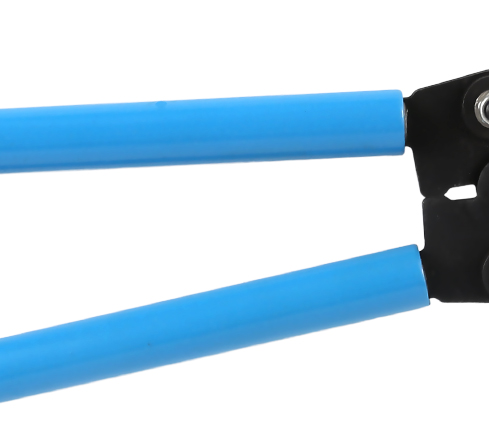

Across construction sites, maintenance workshops, and utility services, there has been a growing focus on practical tools that meet evolving job site demands. Among these, the Heavy Duty Cable Stripper has seen increasing usage in both electrical setups and large-scale utility installations. Its durable build and mechanical efficiency contribute to smoother workflows, particularly in environments where handling thick or layered cabling is part of the daily routine.

Electricians and technicians working with medium to large gauge cables often face challenges in preparing wires for connections. This is especially true when dealing with armored or multi-layered insulation. In these cases, a Heavy Duty Cable Stripper helps streamline the task by delivering consistent results without unnecessary effort. The tool allows workers to expose conductors cleanly while reducing the chances of internal damage, which is important for maintaining safe and effective connections.

At the same time, professionals engaged in plumbing repair or installation frequently need to cut plumbing pipe with precision. Whether working with PVC, copper, or composite tubing, the cutting process must be accurate to ensure a proper fit during installation. While the Heavy Duty Cable Stripper is tailored for electrical work, its mechanical principles—leverage, controlled pressure, and ergonomic grip—are echoed in the design of pipe cutting tools as well. Many multi-purpose contractors prefer tools that can accommodate both cable stripping and assist in their ability to cut plumbing pipe, especially on mixed-discipline jobs.

In many utility installations, access to wiring and piping may be limited by confined spaces or structural obstructions. The compact form factor of the Heavy Duty Cable Stripper enables technicians to maneuver around tight bends and junctions without sacrificing precision. This is particularly valuable in industrial settings or during retrofitting projects where components are installed within older infrastructure. Meanwhile, to cut plumbing pipe in these same restricted areas, professionals often rely on compact ratcheting cutters or close-quarter tubing tools that follow similar engineering principles.

As utility teams expand their range of services, having equipment that functions reliably under demanding conditions becomes a priority. A Heavy Duty Cable Stripper that maintains its cutting edge after repeated use provides measurable value over time. Likewise, a clean ability to cut plumbing pipe reduces material waste and helps prevent leaks or alignment issues. These qualities are not about flair but rather about consistent task fulfillment.

Workplace safety is another reason why these tools are getting attention. Poorly stripped cables or uneven pipe cuts can advance to rework or malfunction. A properly adjusted Heavy Duty Cable Stripper reduces the risk of slicing too deep or leaving jagged edges on insulation. Similarly, using the right tool to cut plumbing pipe ensures a cleaner edge that fits snugly into couplings and seals.

The growing appeal of the Heavy Duty Cable Stripper reflects broader trends in field-ready tool design. It supports accuracy, reduces fatigue, and aligns with the multi-skill roles many technicians are now expected to fill. As cross-discipline work becomes more common—where someone may both wire a junction box and cut plumbing pipe in a single visit—having adaptable, job-proven tools becomes a practical necessity. With continued emphasis on efficient maintenance and reliable infrastructure, tools like the Heavy Duty Cable Stripper are likely to remain a fixture in utility and electrical settings for the foreseeable future.